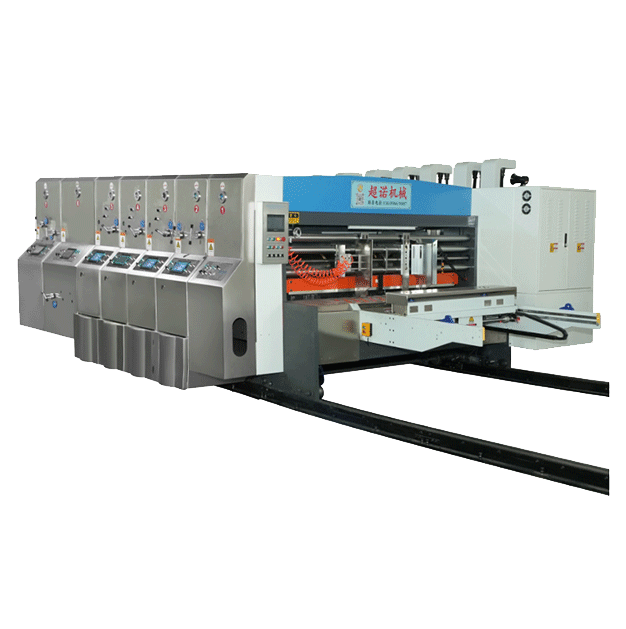

High production capacity and level of automation

By adopting an intelligent production line, high-speed printing, slitting, die-cutting and other processes can be automated. Compared with traditional equipment, the production capacity can be increased by more than 30%, significantly reducing labor costs and making it suitable for the rapid delivery of bulk ordersHigh-precision processing and quality stability

Equipped with precision components such as servo motors and numerical control systems, the printing color registration accuracy can reach ±0.5mm. The dimensional error of the formed cartons is small, and the indicators such as compressive strength and adhesion are stable, meeting the high-standard packaging requirements of e-commerce, logistics, etcEquipment compatibility and flexibility

It supports the processing of various carton specifications (such as three-layer and five-layer corrugated paper) and materials (ordinary paper, eco-friendly paper). Some models can quickly switch between different processes through modular adjustment, adapting to customized production of small batches and multiple batches.

Energy conservation and environmental protection design

Low-energy consumption motors and waste heat recovery systems are adopted. Some of the equipment meets the national energy efficiency standards. The noise and dust emissions during the production process are lower than the industry limits, which is in line with the trend of green manufacturing.Durability and low maintenance costs

The key components (such as rollers and cutting tools) are made of high-strength alloy materials and undergo wear-resistant treatment. The average service life of the equipment can reach over 10 years, with a long maintenance cycle and convenient after-sales parts supply.Perfect after-sales service and technical support

We offer equipment installation and commissioning, operation training, and 24-hour fault response services. Some manufacturers also support remote operation and maintenance systems to monitor equipment status in real time and reduce downtime losses.